Supercritical CO₂ in Thermal Power Generation

Electricity Generation with Supercritical CO₂: Advantages, Applications, and Future

Supercritical carbon dioxide (CO₂) is emerging as one of the most disruptive technologies for high-efficiency power generation, offering superior thermal performance, a smaller environmental footprint, and significant opportunities for integration with renewable energy and thermal energy storage (TES). This technology is part of the key advances driving the transition toward a decarbonized and sustainable industry.

Fundamentals and Advantages of Supercritical CO₂ in Energy

What is Supercritical CO₂ and Why Is It Relevant in Energy?

Supercritical CO₂ is a form of carbon dioxide obtained by subjecting it to pressure and temperature above its critical point (31.1 °C and 73.8 bar). In this state, CO₂ exhibits both gas-like and liquid-like properties, making it extremely efficient as a working fluid in advanced thermodynamic cycles.

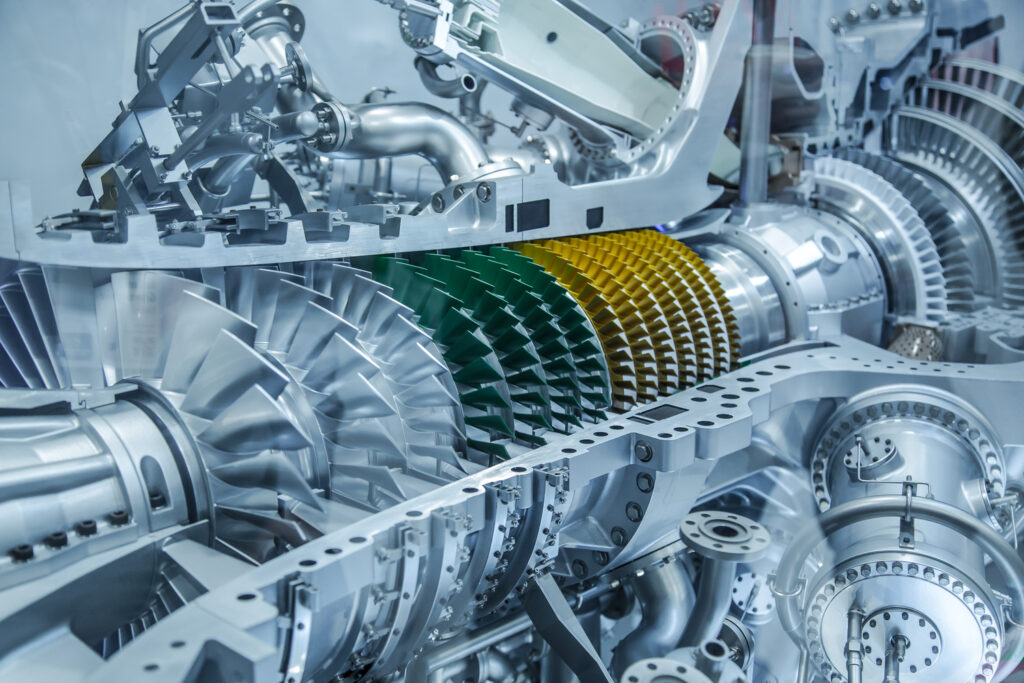

Its use in closed Brayton cycles enables more compact, efficient, and flexible energy conversion compared to conventional water-steam systems. This innovation is a key tool to enhance the performance of solar thermal, geothermal, and biomass power plants, and holds great potential for waste heat recovery in industrial processes.

Technical Comparison: Supercritical CO₂ vs. Steam

As thermal generation technologies evolve, supercritical CO₂ is emerging as a high-performance alternative to traditional steam turbine based systems. Key technical differences include:

Operating Temperature:

Supercritical CO₂: Reaches up to 700 °C, enabling higher thermal efficiency.

Steam: Limited to 540–600 °C due to material constraints.

Operating Pressure:

Supercritical CO₂: Operates at very high pressures (80–300 bar), improving energy density.

Steam: Typically operates at 100–180 bar.

Thermal Efficiency Potential:

Supercritical CO₂: Can achieve 45–55% efficiency with heat recovery.

Steam: Generally ranges between 35–42%.

System Size:

Supercritical CO₂: Allows for compact design—ideal for modular or space-constrained plants.

Steam: Requires larger equipment, increasing structural complexity.

Startup Time:

Supercritical CO₂: Enables rapid start-up, well-suited to hybrid systems and variable renewable input.

Steam: Slower response times due to thermal inertia.

Integration with Thermal Energy Storage (TES):

Supercritical CO₂: Highly compatible, especially with solar concentration or advanced combined cycles.

Steam: Efficiency decreases when coupled with TES.

Advantages of Supercritical CO₂ in Power Generation

High Thermal Efficiency: Carbon dioxide energy cycle converts heat to electricity more effectively than traditional technologies.

Smaller System Size and Cost: Less bulky components, reduced need for cooling systems.

Flexible and Fast Operation: Suitable for complementing intermittent renewables like solar PV.

TES Compatibility: Enhances energy management when integrated with thermal storage.

Low Environmental Footprint: Minimal emissions, no toxic fluids, and no rare materials used.

Applications and Projects of Supercritical CO₂

Pilot Projects in Brayton Cycles with Supercritical CO₂

At the international level, various energy research programs are developing and validating closed Brayton turbines using supercritical CO₂ as the working fluid (carbon dioxide energy cycles). Highlights include:

STEP Demo Project (USA), led by the DOE and GTI Energy, with a 10 MW pilot plant.

SCARABEUS Project (Horizon Europe), which investigates Brayton cycles with doped CO₂ for temperatures above 700 °C.

Re-CO2ST, focused on industrial waste heat recovery through compact supercritical cycles.

These tests validate the commercial viability of supercritical carbon dioxide in the short term.

Success Cases of Supercritical CO₂ in Industry and Research Centers

Several research centers such as Sandia National Laboratories, CIEMAT, DLR, and NREL are leading real-scale prototypes and industrial collaborations. Some application examples include:

Integration with solar thermal plants in California and Nevada.

Trials in high-temperature industrial processes like cement manufacturing and steelmaking.

Pilots in high-enthalpy thermal storage with molten salts and CO₂.

These projects lay the foundation for the industrialization of generation plants using supercritical CO₂.

Innovation in Supercritical CO₂ Generation Systems

The development of materials resistant to high temperatures and pressures, as well as advanced thermal control systems and compact turbine designs, is accelerating the technological maturity of supercritical CO₂.

Moreover, its potential in hybrid environments (e.g., coupled with green hydrogen, biomass, or thermal storage) positions it as one of the key technological pillars for low-emission thermal generation.

Technological Challenges and Future Perspectives of Supercritical CO₂

Materials, Operation, and Safety Challenges

The use of supercritical CO₂ in thermal power generation faces significant technological challenges, especially regarding:

Materials resistant to high temperatures and pressures, since supercritical CO₂ can be corrosive and expose equipment to extreme conditions (up to 700 °C and 300 bar).

Sealing and leak control, given that the supercritical fluid has properties between gas and liquid, complicating the tightness of turbines and compressors.

Operational safety, requiring precise monitoring and advanced control systems to prevent overpressure or thermal instabilities.

Costs of specialized components, still high due to the low industrial-scale production of certain equipment adapted to these conditions.

Overcoming these challenges is key to establishing supercritical CO₂ as a viable and scalable technology in the energy sector.

Perspectives in Hybrid Grids and Microgrids

Supercritical CO₂ offers unique advantages for integration into hybrid energy microgrids, especially those combining:

Concentrated solar power (CSP) with thermal energy storage (TES).

Distributed generation with flexible demand management.

Industrial electrification in environments with energy variability.

Thanks to its fast startup and high efficiency, Brayton systems using supercritical CO₂ can operate as backup or baseload power sources, facilitating the operational stability of complex or isolated electrical grids.

This positions supercritical CO₂ as a strategic solution for areas with high solar irradiation or developing infrastructure, offering resilience, modularity, and superior thermal efficiency.

Linking Supercritical CO₂ to Energy Transition and Decarbonization

The transition to a low-carbon energy matrix requires technologies that:

Reduce CO₂ emissions without sacrificing efficiency or reliability.

Complement intermittent renewable sources like solar and wind.

Improve energy integration in heat-intensive industrial sectors.

In this context, supercritical carbon dioxide, coupled with solar thermal energy and TES, emerges as a key tool to:

Decarbonize high-temperature thermal processes.

Store and release energy flexibly, reducing dependence on fossil fuels.

Increase energy efficiency of new clean thermal generation plants.

The Role of RPow in Carbon Dioxide Cycles Engineering

Projects and Collaborations with Technology Centers

RPow actively participates in R&D projects on supercritical CO₂, collaborating with:

European technology centers specialized in thermal energy and advanced fluid dynamics.

Universities and institutions researching new thermodynamic cycles and materials.

European programs such as Horizon Europe, focused on developing sustainable energy generation infrastructures.

These collaborations enable RPow to be at the forefront of technological development, providing high-level applied engineering throughout all project phases: from conceptual design to operational validation. An example of this type of R&D project is sCO2OP-TES – RPOW – Renewable power onwards.

Integration of Supercritical CO₂ with TES and Renewables

One of RPow’s areas of expertise is the integration of supercritical CO₂ with thermal energy storage (TES) and renewable energies, such as:

Concentrated solar power (CSP) plants based on Brayton cycles.

Hybrid solar-thermal and photovoltaic systems, where stored heat can be efficiently converted into electricity.

Industrial solutions requiring high-temperature process heat, such as foundries, ceramics, or petrochemicals.

RPow designs and adapts systems to achieve maximum energy efficiency and effective emissions reduction, applying emerging technologies like advanced heat exchangers and digitized thermal control. An example of this type of project is: Supercritical CO2 cycle feasibility study – RPOW – Renewable power onwards

RPow’s Commitment to Energy Innovation

In all its projects, RPow demonstrates a strong commitment to innovation and energy sustainability, integrating:

Cutting-edge technologies, such as supercritical CO₂, modular TES, and intelligent thermal control systems.

Scalable and replicable solutions for the industrial and energy sectors.

Strategies aimed at decarbonization, aligned with European climate neutrality goals for 2050.

This approach makes RPow a benchmark in advanced thermal engineering, capable of transforming energy R&D into real, efficient solutions for the global market.

Renewable

Power Onwards

Engineers with more than 20 years of experience